This 18-year-old tinkerer’s innovation can ‘terminate’ coronavirus from surfaces

Mihir Vardhan, a passionate tinkerer from Gurugram, created the ‘Terminator’ series, devices that disinfect surfaces and objects, to help people fight the coronavirus.

The COVID-19 pandemic has led to many people prioritising their hygiene. Over the last two years, several innovations have also been launched to help people maintain their hygiene at a larger but easier scale.

One among them is Mihir Vardhan, a second-year student of Engineering at the University of Illinois, USA, who developed the ‘Terminator’ series, devices that work on the principles of UV disinfection.

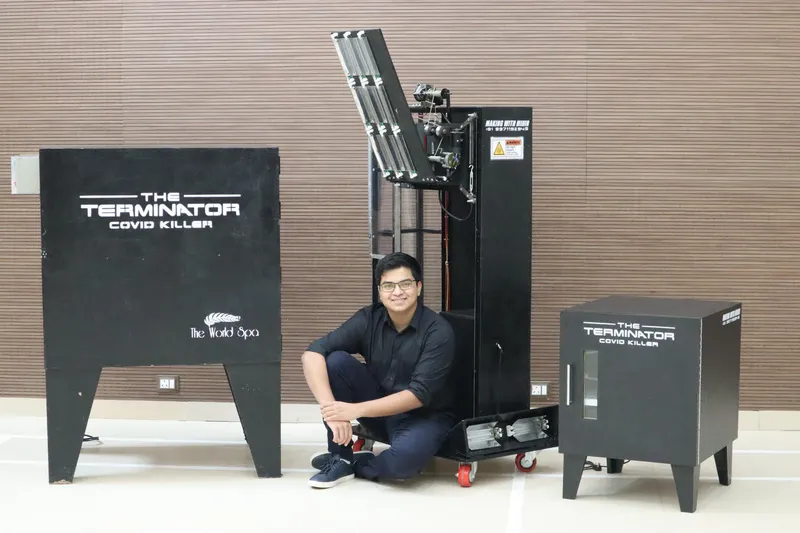

The 18-year-old from Gurugram came up with three innovations – Terminator Mega, Terminator Mini, and Terminator Turbo.

“When COVID-19 struck and UVC-sanitisation devices became available for small objects, I saw the urgent need for a high-capacity device that could sanitise large objects effectively and efficiently, and I took on the engineering challenge of designing and building one, and the Terminator Mega turned out to be my first real engineered product,” Mihir tells SocialStory.

Mihir Vardhan

‘Terminating’ the coronavirus

The Terminator Mega is a high-capacity, 1,000-litre, UVC sanitising chamber designed to sanitise large items. The prototype got Mihir his first order for two units, and then orders for 12 more, including one from the Prime Minister’s Office.

He also received orders for smaller units for homes for a 200-litre capacity device, which is called the ‘Terminator Mini’.

Built for commercial use, both devices are robust, easily replicable, and easy to maintain and service. The chambers are made of wood, lined with aluminium to prevent leakage of the UVC radiation, and to also increase device efficiency by providing a reflective surface inside the chamber. The wiring and UVC tube lights are locally sourced. While Terminator Mega costs about Rs 28,000, Terminator Mini is Rs 20,000.

“Two companies reached out to partner with me to commercially manufacture the units. With the design replicable commercially, I decided to share it with them and move on to my next challenge – addressing the feedback by users of the Terminator Mega and Mini,” says Mihir.

The question was — Is it possible to build a device that can sanitise much larger, more complex objects, maybe even entire rooms, using UVC?

Mihir began to ideate further. The challenge was not just to sanitise regular surfaces, but also do it for those with varying heights and angles. The same was to be executed in lesser time than it would take to manually rub all those items with sanitiser and bleach.

Mihir with the three Terminator models.

“I studied the tower design and other designs being used across the world for this purpose and was inspired by Dimer’s UV hammer. With the objective of building a device that would be more affordable and more accessible, I took on the challenge of building a device with similar functionality, in under $300, and within seven weeks (the time I had before I left for college) and the Terminator Turbo was born,” he shares.

The Terminator Turbo is a 6-foot tall, 55-kilogram robot that can, using UVC light, sanitise any object or space, at any height and any angle, in a fraction of the time and cost that it would take to effectively sanitise the same object or space using chemicals, hence eliminating any exposure to the virus or the harmful chemicals used to destroy it.

It provides a highly efficient, effective, and relatively inexpensive sanitisation solution for large, high-traffic, high-infection-risk areas like hospitals, airports, clinics, schools, gymnasiums, hotels, restaurants, and so on.

The Turbo is a prototype and was built largely out of recycled materials – windshield wiper motors and bearings from roller skates to enable movement of the drawbridge, an encoder from an Otis elevator to monitor the speed of motion, UPS batteries to power the UVC lights, and a door closer mechanism from the bedroom to maintain tension on the drawbridge.

“While there are devices available with similar functionality, they are right now out of reach for many potential users, especially in the developing world. Produced at scale, devices like the Terminator Turbo will play a very significant role in controlling the spread of infectious diseases,” says Mihir.

Challenges

The two challenges while building the Terminator Turbo were ensuring that it did not require any complex tools or parts that were not available during the lockdown, and keeping the build cost to the minimum to ensure that the robot remained affordable, says Mihir.

“Since I did not have access to a machine shop or workshop, I am really proud to say that this super-large robot was built in my living room in Gurugram, and building it taught me trades I might never have learnt otherwise – grinding, sanding, painting, welding, carpentry and a great deal of patience with the many iterations some parts had to go through,” he shares.

“The cost for the first two Terminator Megas was funded by my condominium as they had requested a device for sanitisation purposes. When I received an order for my first commercial unit, my parents funded it and then, as the Megas and Minis went commercial, I became self-funded,” adds Mihir.

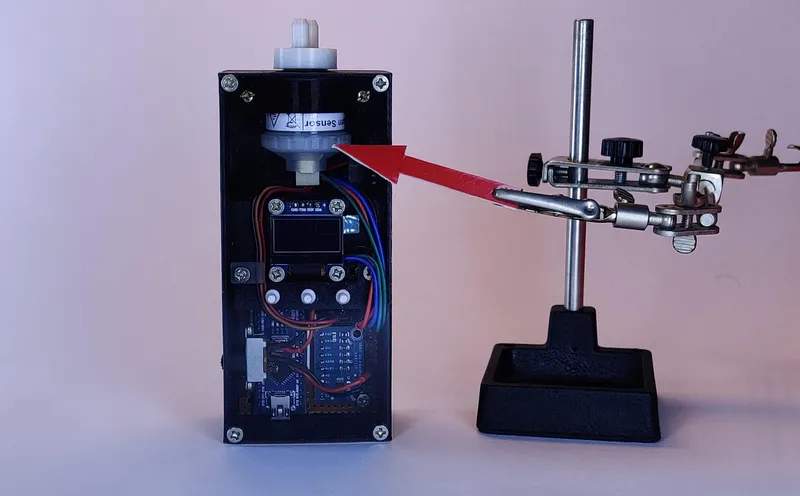

Mihir's prototype of the O2D2

Making with Mihir

Mihir has been passionate about robotics for a long time and started his tinkering journey from middle school with Avishkaar Robotic Kits. He launched the YouTube channel 'Making with Mihir' in 2016 to inspire more youth to join the maker movement.

“However, I soon realised that the DIY project videos I had been making were enjoyed by robotics enthusiasts but were not inspiring everyone and may, in fact, have been doing just the opposite,” he says.

He found that interesting and comical robots were the best way to show people the fun and interesting side of Engineering that he fell in love with. In fact, his ‘Robot-That-Shoots-You-In-The-Face’ build has been the most popular so far.

“I like to challenge myself to build ‘frugally’ — recycling, reusing, and conserving resources. Not long ago, I started to focus on how my builds can make a real difference in the real world and I started building devices to address real world problems,” Mihir shares.

Soon after, he went on to create the Terminators and also a device called O2D2

“A few months ago, there was an urgent need to build a product to assess oxygen output at various flow rates to determine the effectiveness of the concentrator. And that led my latest build – O2D2 – a fully open-source DIY Oxygen analyser,” he shares.

Talking about the road ahead, he says, “I will make the most of the opportunity I have to study at one of the best engineering schools in the world, and the opportunity I have to do research work with one of the leading research scientists at UIUC, Dr Arijit Banerjee,” he says.

“At the same time, I plan to continue to tinker, to inspire youth in the world of STEM, to work on practical and affordable engineering solutions where needed, and to commercialise them if the opportunity presents itself. My long-term goal is to build an engineering organisation that will research and build for a better future,” Mihir signs off.

YourStory’s flagship startup-tech and leadership conference will return virtually for its 13th edition on October 25-30, 2021. Sign up for updates on TechSparks or to express your interest in partnerships and speaker opportunities here.

For more on TechSparks 2021, click here.

Applications are now open for Tech30 2021, a list of 30 most promising tech startups from India. Apply or nominate an early-stage startup to become a Tech30 2021 startup here.

Edited by Saheli Sen Gupta