Top 3 ways of improving supply chain performance

In the recent survey, the companies are facing laborious challenges. The big switch in consumer demands has made the distributors, wholesalers, retailers or manufacturers shortage or inefficiencies of products and services. For some products, the consumption is improving ensuing in real struggles meeting those needs.

"Good collaboration heightens strength, but poor collaboration is terrible then no collaboration at all".

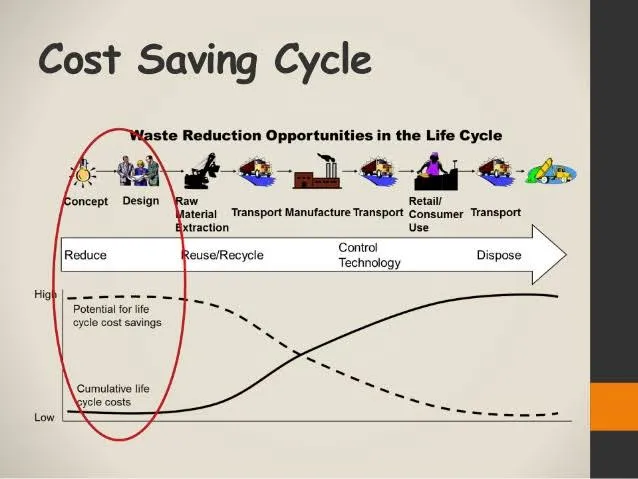

Recent research reports that useful Supply chain management (SCM) minimizes non-value-added activities and associated investment cost and operating cost, augment customer responsiveness and flexibility in the supply chain and enhance bottom-line performance and cost competitiveness.

The long term collaboration with suppliers can aid in superior results and value enhancements. The collaborative buyer-supplier relationship improves organizational goals and for efficiently controlling the business activities.

"Real competition is not company against the company but rather supply chain against supply chain".

Large retailers have shored up their supply chain with modern technology including cloud-based, AI-driven analytics and IoT sensors. The advanced technology gave birth to real-time insights. From the operational efficiency, Walmart and Amazon are pretty ready.

In addition, the right performance measurement tool improves the efficiency and effectiveness of a supply chain. It reduces operating costs and customer service in logistics activities, improves a firm’s revenue growth, and enhances shareholder value.

The benefits of building trust in the business relationship reduce transaction costs in an exchange relationship boost the long term orientation, Engaging in future business opportunities and facilitate states unified transactions.

Improved communication plays a vital role in social and business relationships. It might bring up the issue of difficulties in cross-cultural communication and information sharing as they can be a significant obstacle to business.

Personal relationships play a significant role in businesses and are a critical precondition for effective business. Lacking to understand cultural differences in relationships and networks were not able to manage the long-term business.

With this in mind, here are the top 3 benefits of long term supplier relationships.

1) Pricing volatility mitigation

Open book policies and negotiated margins allow both the parties from fluctuation in the market and pricing.

2) Supply chain consolidation

The implementation of supplier chain consolidation on the production and indirect levels aims to reduce supply costs and improve efficiency.

3) Lowered costs

Better relationships and increased interaction can cut the unnecessary costs arising from re-tendering or re-negotiating.

4) Improved efficiency and communication

This allows greater integration of business, IT and financial processes making any issues to vanish.

Altogether these strategies reduced purchase prices, reduced process costs, reduced risk, and improved supplier relationships to the next degree. With a diverse global supply chain, it is always vulnerable to disruption from outside factors such as natural disasters, shortages, tariff or geopolitical clashes. For such crisis resilient and adaptable contingency plans to be built in. Develop different levels of contingencies to withstand new stage of the crisis. Demand can be unpredictable during the crisis, the companies need to look for steps that can facilitate real time collaboration and communication. Explore using advanced technologies such as artificial intelligence or the internet of things to identify trends, forecast potential problems and find solutions. Here we are in the middle to cover things, so we need to nimble to be able to change by improving the visibility of end to end supply chain. The tools like slack, We chat, google handouts, whatsapp and other online platforms can keep team and suppliers connected across countries and continents.

When something like natural disasters hit, consumer behavior changes. Keep a close eye on consumer behavior so that you can redirect product levels based on the changes.