How you manage your bottlenecks will determine your profits

Dr Eli Goldratt’s Theory of Constraints exhorts businesses to identifying the most important limiting factor, the constraint, that stands in the way of achieving goals and systematically improving that constraint.

In a Harvard Business Review article, Scott Anthony shared some insights about S&P 500 companies.

- 61-year tenure for average firm in 1958 narrowed to 25 years in 1980 - to 18 years in 2012

- At current churn rate, 75% of the S&P 500 will be replaced by 2027

Do you know of any company that reports infinite profits? Certainly none. This verifies that something exists that limits the profits of an organisation. That something is a constraint on the performance of the organisation. Just as the strength of a chain is dictated by its weakest link, the overall performance of any company is dictated by its constraint. The constraint might be in operations, ability to generate new orders, capability of procuring raw material, or even the market size itself! If you can find a way to manage the constraint you can dramatically increase sales, cash, and profit without any significant investment.

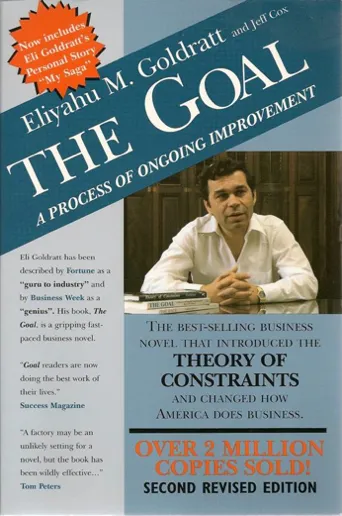

Dr Eli Goldratt first introduced Theory of Constraints (ToC) in his best-selling book THE GOAL. Millions of people around the world could relate to Alex Rogo and his tale of turnaround at Unico manufacturing plant. The book has featured on Time magazine’s list of top 25 five most influential business books of all time. Jeff Bezos, Founder of Amazon, has often shared that THE GOAL is one of the top three books he recommends to his top team.

Due to the overwhelming popularity of The Goal, most people assume that ToC is applicable to manufacturing only. Companies that have implemented ToC understand that it is a holistic philosophy, with as much application to strategy and marketing, as it does to production and operations. ToC has been successfully applied across sectors including automotive, consumer goods, insurance, high-tech, FMCG, apparels, logistics, government, steel, projects, retail, education, healthcare, to name a few.

In THE GOAL, Alex comes across his old college professor, Jonah, who guides him through a series of questions that make Alex and his team brainstorm and come up with solutions to save the plant. This is done through the Socratic method, explained in the book through relatable, real-life situations.

Interestingly, Alex finds a breakthrough while leading his son’s boy scout hike. Alex’s goal is to keep the troops together during the hike. However, due to the difference in pace of each child, every now and then, large gaps start coming in between the boy scouts. That makes it difficult for Alex to keep them together. He identifies that one of the boys named Herbie is the slowest in the group. He further realises that no matter how fast the other boys walk, their time to reach their destination will be dictated by Herbie’s pace.

Drawing on this analogy of boy scouts, he discovered that only one factor determined how fast they would get to their destination – Herbie. To keep them together and maximise their speed, it was best to let Herbie set the pace. Herbie was moved to the front of the line, and they did everything they could to lighten his load and help him move as fast as possible.

ToC provides a simple and effective process for system improvement or five focusing steps, outlined below:

1. IDENTIFY the system’s constraint

What is it that is limiting you from getting more of your goal units? The constraint could be in customers, orders, operations, suppliers, or cash. For a new business, it could be the number of customers. For an established business, let’s say a popular cafe or eatery, the constraint could be the seating capacity. For a fashion retail chain, the constraint could be the availability of fast moving items.

Constraints can be tangible or intangible. A physical constraint might be a resource or a machine. Constraint could also refer to quality/supply issues or unavailability of input material. It may also refer to a particular department or trained manpower. It could also be a policy constraint, a written or unwritten policy that prevents the system from making more.

"We very rarely find a company with a real market constraint, but rather, devastating marketing policy constraints. We rarely find a true bottleneck on the shop floor, we usually find production policy constraints. We almost never find a vendor constraint, but we do find purchasing policy constraints. And in all cases the policies were very logical at the time they were instituted. Their original reasons have since long gone, but the old policies still remain with us," Dr Eli Goldratt writes.

In 99 percent of the cases, we find that there isn’t a tangible constraint. It is usually a policy constraint. It means capability already exists; we are simply holding ourselves back based upon some internally held assumptions or beliefs.

2. Decide how to EXPLOIT the system’s constraint

Exploiting the constraint simply means getting the most possible out of the existing capacity of the constraint. For many new businesses, customer acquisition is a challenge. A lot of marketing budget is spent to widen the reach of new product or service. Can we take a pause and evaluate how satisfied our current customers are? How many new customers are coming from customer referrals?

A constraint in the number of customers implies that we have more capacity in operations than the customer orders. This means that existing customers should get the best possible experience. Therefore, before increasing marketing spend to acquire new customers, we must ensure that we’re getting a sizable chunk of the existing customers’ wallet.

Several software services providers face issues in delivering projects on time. Often, there are resources with certain technical skills that are in short supply and their availability becomes a bottleneck for timely project completion. Can we take steps to ensure that we get the maximum capacity out of these trained resources? If they are involved in anything that does not require their technical skills, it should be offloaded to someone else. Any documentation work/meetings that can be handled by a subordinate/ superior should not be handled by the bottleneck resource. If this resource is working on several projects, efforts should be made to reduce bad multitasking by providing a clear priority system. The trained resource should not even have to waste any time deciding which task to work upon, which one to delay.

3. SUBORDINATE everything else to the above decision

Our decision to manage the weakest link must be backed by the way we manage the other links. All policies and measurements must be designed to get the most out of the constraint. Essentially, when the constraint is not working, no one in the organisation is working. Non-constraints must work to the meet the requirements of the constraints. This step is often missed, and thereby the majority of financial benefits of ToC are lost. This is the toughest step.

Let’s understand the meaning of subordination using the example of a hospital. The surgeons are probably the busiest resources; there is a lot more demand on their time than the capacity they have. So, hospitals have designed procedures to ensure that surgeons focus on their core skill and the rest of the resources work according to their availability. By the time the surgeon reaches the operation theatre, the patient is prepared for surgery, and all medical equipment, consumables, medicines and the supporting team are ready. The idea is that the surgeon should not waste even a minute waiting for the preparation; s/he reaches and starts the surgery without any delay. Wouldn’t it be a travesty, if the surgeon reaches and has to waste precious time because the supporting team is not ready?

4. ELEVATE the system’s constraint

Most of the time, the first three steps are enough to get sufficient output from the constraint. If still more capacity is required, then look at adding more resources. However, before you make this decision, ask yourself if the second and third steps have been followed completely. Before hiring new people, can we try to upskill existing ones? Are the market conditions, product mix, type of customers/ orders expected to be the same as today? Are we reasonably sure about the market requirements in the near future? If you’re not sure, but you still need more capacity, try to get more by offloading work, upskilling, outsourcing, getting consultants, gig workers – whatever you need. Don’t be in a rush to hire new people, invest in new technology, or set up a plush office because you have the cash TODAY.

What is the risk here? It is very easy to hire people but not as easy to fire. More importantly, it breaks trust and demoralises existing employees. Also, you may not always be as cash rich and these fixed expenses can hit really hard in tough times.

5. Don’t let INERTIA be the system’s constraint. Go back to Step 1!

If, in a previous step the constraint is broken, go back to the first step. Do not let inertia be the system constraint. Often when a new constraint is identified, it is necessary to change the policies you have just made. Frequently shifting constraints wreak havoc on policies, procedures, and people.

The long-term strategic application of ToC does not call for continuous removal of all constraints. In any case, there will always be one constraint. The idea is to CHOOSE where the constraint should be to best exploit market opportunities, and then keep it there. Decide if you want the constraint to be internal or external. Will it be in operations or customers? This also means very consciously choosing which market segment to cater to. And which target groups not to cater to.

ToC is a holistic approach that advocates simplicity over complexity. However, we know from experience that what is simple is not always easy. It requires focus, planning, and synchronisation, so that the combined efforts of different functions result in a quantum jump in the performance of the system. ToC provides the necessary tools and techniques to achieve this jump in performance. Most companies are able to see improvement in financial performance within 13 weeks from the start of implementation.

(Disclaimer: The views and opinions expressed in this article are those of the author and do not necessarily reflect the views of YourStory.)