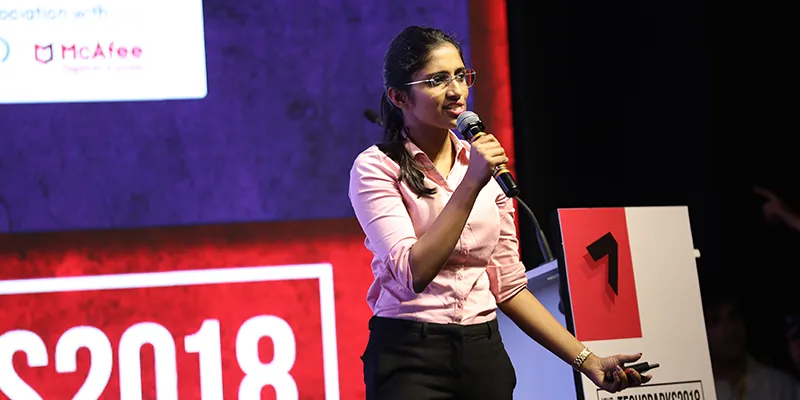

[Tech30] What can you do with the waste you produce? This 23-year-old has answers

Bengaluru-based TrashCon was chosen as a Tech30 startup this year. The company segregates and recycles solid waste after it is collected from your home.

How many of us think about our discarded household waste, and where it goes? Every day, we can see a stinking truck carrying garbage from our ward to a dump yard. We choose to either cover our noses in disgust, zoom past, or take a different route to avoid the stench.

“My friends took a different lane to reach college, because that lane had a huge dump of garbage each day,” says TrashCon founder Nivedha RM.

A graduate from Bengaluru’s R.V. College of Engineering, Nivedha took up the challenge of waste segregation, but not at the source of its generation like it is currently dealt with.

She has designed a waste segregating machine that can process municipal waste in bulk after it is collected, and segregate wet waste from dry. The USP of the machine – “Come what may, the machine will shred it,” she says.

Why segregate after collecting?

“For ages, we’ve been told to segregate waste at home, which has not happened yet. We cleaned up the lane to find a heap of garbage the very next week,” says Nivedha. She went to the Chief Engineering Officer of her college’s ward to address this issue and he said, “Come back with a solution that adds value to garbage.”

This inspired her to think about creating a decentralised approach. With the help of her mentor, Saurabh Jain, she came up with this model of 'shredder'.

Each day, for the past one year, Nivedha has been defeated by a dump yard. Experimenting with different shredder prototypes in her college lab, she was unable to build the right machine, despite identifying the problem. This is where Saurabh, being an electrical engineer, helped.

Today, Nivedha is planning to set up her own manufacturing unit in Peenya Industrial estate with a team of six. “The outsourced manufacturer could not build a shredder that could chop everything. We will start manufacturing once we get orders for six machines,” says Nivedha.

How the machine works

The mixed waste filled in plastic bags is cut open by a bag breaking system and then sent into the shredder through a conveyor belt.

“Since a single-sized knife cannot cut all kinds of waste material, we had to go back and research to overcome this problem,” says Nivedha. She decided to design an in-built air blower, which would blow away less moist particles and segregate the wet waste.

TrashCon’s shredders generate two streams of waste – biodegradable and non-biodegradable.

The biodegradable component is processed into manure and biogas. She says, “Manure is sold by communities and the municipality. We sell the biogas to Shell.”

She claims that one of these machines is currently at work in Srinagar ward (no 156), in Bengaluru, processing five tonnes of municipal waste each day.

Funding and revenue

Everyone, including townships (with more than 500 households), corporate, and municipality and waste management companies, can use this shredder as long as the waste is in bulk, says the founder.

Currently, there are four types of machines that can process quantities weighing 500 kgs, two tonnes, 5 tonnes and 10 tonnes every day, respectively. The machines that can process 10 tonnes costs Rs 35 lakh.

Nivedita was able to build this product with the help of her mother’s savings and funding from IIM Bangalore’s incubation centre.

Business model

The shredded plastic at the end is compacted into cubes on a weekly basis, “But we are yet to price it,” says Nivedha.

The plastic is also used to manufacture tiles and shutters. She further explains that any kind of furniture made out of plywood could be replaced by this material, because it’s lighter, water resistant and does not bend.

The sector

According to a Central Pollution Control Board (CPCB) report, less than 15 percent of India’s municipal waste is being processed or treated. A report by Ellen MacArthur Foundation states that implementing these close looped cycles in India can yield over $624 billion per annum in material savings by 2050.

There are several startups looking to solve this problem. Bengaluru-based Sahas Zero Waste works on waste recycling but it segregates waste at the source, collects and pre-processes all waste streams before giving it to specific recyclers. And the loop is closed by selling these recycled products.

GPS Renewables, also based in Bengaluru, manages urban organic waste, turning kitchen and other organic waste into biogas. Pune-based Protoprint converts plastic waste into filaments for 3D printing, and partners with rag pickers to access plastic.

Nivedha’s company has filed three patents in India and one internationally for its in-house technology. By 2020, it plans to manufacture 250 machines.

“Other than our operations in the Srinagar ward, we have signed a LoI with Adaani,” she says.

![[Tech30] What can you do with the waste you produce? This 23-year-old has answers](https://images.yourstory.com/cs/wordpress/2018/10/Trashcon.png?mode=crop&crop=faces&ar=2%3A1&format=auto&w=1920&q=75)