Biotech startup Next Big Innovation Labs takes a big step with govt grants

Thanks to a Rs 49-lakh grant from the Karnataka government, biotech startup Next Big Innovation Labs is ready with the first version of its 3D bioprinter as well as products that help surgeons and drug companies.

A bootstrapped biotech firm that built a 3D bioprinter prototype has suddenly found wings after it bagged a government grant.

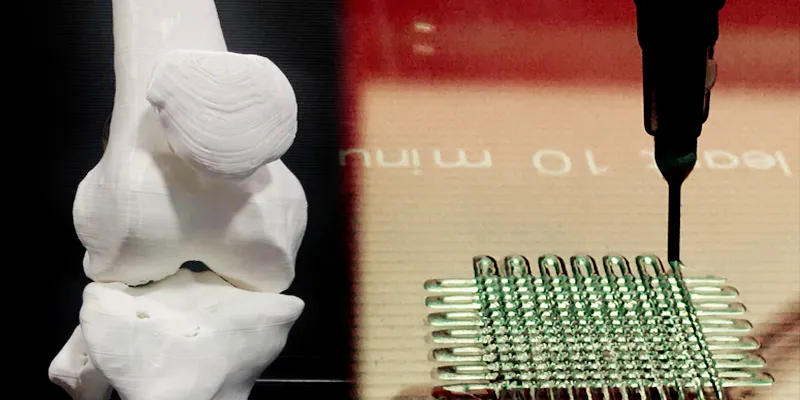

Founded in 2016, Next Big Innovation Labs (NBIL) is disrupting the 3D healthcare sector by coming up with various applications – from 3D bioprinting to sub-products such as 3D printed tissues.

The startup is helping reduce drug-testing cycles for pharma labs as well as working with maxillofacial surgeons to help them hone their pre-surgical skills before undertaking complex reconstruction surgeries. It is also in the process of completing tests on their its prototype version of the 3D bioprinter, which has already elicited keen interest among research and development labs, institutes and educational institutions.

“The lab is working at the intersection of engineering and biotechnology. The large application base is thanks to the four co-founders who come from diverse backgrounds,” says Alok Medikepura Anil, co-founder, NBIL.

NBIL is working with Mazumdar Shaw Centre for Translational Research to test novel material composites and patterns for the development of 3D bio-printed scaffolds for both in-vivo and in-vitro uses. Pooja Venkatesh, Co-founder, says,

3D printed scaffolds have proven to be better alternatives to 2D cell cultures used in most labs today and we are looking at bringing our 3D printed scaffold and tissue assay products to R&D centres.

Co-founder Piyush Padmanabhan adds: “During novel drug development, single layer 2D cell cultures are unable to accurately predict the traces of efficacy or toxicity in hundreds of molecules tested. 3D bioprinting can be done with liver cells and this cuts down costs in identifying right molecules to move past the pre-clinical trial stage and bring the drugs faster to the market.”

Piyush brings in sales and marketing experience from Biocon and Roche, where he worked in renal and liver transplantation segments.

To achieve all this, printing accuracy is needed. “We have built the bio-printer from scratch. Our goal is to build India’s first indigenous 3D bioprinter and its sub-products including tissues,” says Alok, a World Economic Forum Global Shaper. He used 3D printing extensively for applications ranging from automotive to aerospace while he was at Boston University and Cranfield University.

As the co-founders’ long-term vision is to print human organs, the company received Rs 49 lakh under the Idea2POC grant from the Karnataka government. It helped make the prototype as well as devise uses for different fields. The Idea to Proof of Concept grant had selected 26 companies and individuals who were deemed capable of creating a deep impact in the lives of people through tech-based innovation.

State IT and BT Minister Priyank Kharge said biotech companies were being funded by the government for the first time. “This grant, without any equity, offers entrepreneurs and developers a holistic system to explore, develop and launch their ideas. The Idea2POC scheme is designed to identify, mentor and fund enterprising startups based out of Karnataka but which can create a deep impact across the globe with its innovation.”

Also read: Biotech funding round pushes the envelope of tech-based innovation

NBIL certainly fits the bill as its long-term focus is on solving the organ shortage for patients on transplant waiting lists.

“From printing skin layers with live cells called skin tissue assays to developing support structures called scaffolds, the three-dimensional bio-printing models are going to change the way Indian biotech firms and R&D labs approach their work,” says Co-founder Ratandeep Bansal, who has diverse experience in design, automation and manufacturing.

These skin tissue layers can also help burn victims where it can be used as alternate skin grafts.

Ready to scale

The bootstrapped company was running out of a friend’s house earlier before being incubated at the Bangalore Bioinnovation Centre run by the Karnataka government.

The company is in the final stages of testing version 1 of their 3D bioprinter, which they strongly feel will provide Indian researchers with the freedom to conduct their experiments at a nominal cost, as compared to the current expensive 3D bioprinters brought in from abroad. The company is all set to scale up as they are currently building custom 3D bioprinters for leading research institutes to cater to their specific requirements.

Aiding drug development

The startup aims at developing products to enhance the current status of drug discovery and drug development, thereby potentially reducing the overall cost of developing new drugs and the long timelines involved for pharma majors. They are hopeful their 3D tissue assays will play a vital role as labs can test new drugs even before it moves onto the stage of animal testing.

As they are focused towards their goal of improving clinical outcomes, NBIL is currently working with leading maxillofacial surgeons and has developed a custom solution to 3D-print a patient’s skull structure by using CT scans. “NBIL’s 3D printed skulls have been used as pre-surgical tools and teaching equipment in India and Ethiopia. We are currently looking at further improving this technique,” says Pooja, who oversees the research activities.

Bengaluru-based maxillofacial surgeon N. Srinath says he uses these 3D printed stereolithographic models for pre-surgical analysis, cases in trauma, implants, reconstruction and other such cases. “The models printed are accurate and helps me analyse challenges before going into surgery,” the doctor says.

Grant helped fast-track growth

“The Karnataka government’s Idea2PoC grant has given us the necessary support to fast-track our journey towards building a completely indigenous 3D bioprinter. We intend to market the 3D bioprinted products to leading pharma, cosmetic and academic research labs and this is aimed at rethinking the way conventional drug delivery and animal testing is done as of today,” says Harish Setty, who takes care of government and business at NBIL.

Piyush says the grant has certainly helped achieve key milestones.

We have been able to finalise version 1.0 of the 3D bioprinter that we are developing, have worked with more R&D partners, worked with leading research labs to develop novel materials for scaffolds and bioinks, received pre-orders for custom 3D bioprinters, worked towards development of 3D printed tissue assays for the cosmetic and pharmaceutical sector and have ongoing collaboration with leading maxilla-facial surgeons and hospitals to understand the impact of 3D bioprinted tissues.

These are the kind of milestones that the government would be looking for too. “The aim is to discover and encourage such innovators who need early-stage funding to reach commercial capabilities of their research efforts. The government will provide long-term support and help them scale up,” says Gaurav Gupta, Principal Secretary, IT, BT and S&T.

NBIL has also been shortlisted as one of the top 50 companies under TATA-DST-Lockheed Martin's India Innovation Growth programme.