This project in Munnar is providing livelihood options to hundreds of differently abled young adults

Aranya Natural creates all-natural dyes extracted from locally sourced, natural resources found in Munnar, Kerala.

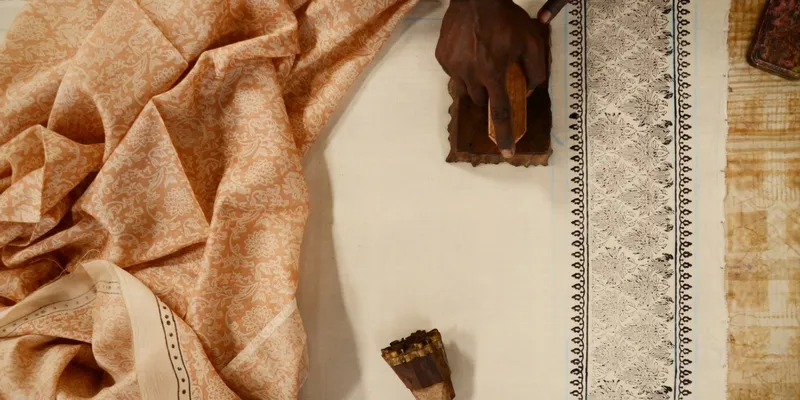

Nestled in the Kanan Devan Hills in Munnar, Kerala, is Aranya Natural. This natural dye-making unit gathers the nature’s bounty and converts into bold and ethnic printed designs.

Aranya Naturals is one of the four projects at Srishti Welfare Centre, a community development project supported by Tata Global Beverages which focuses on rehabilitation of specially abled children.

Restoring the fading arts

With an aim to educate and rehabilitate and also provide sustainable livelihood to the challenged young adults emerging from DARE (Developmental Activities in Rehabilitative Education) school, the members of Srishti Trust sought to start of natural dyeing unit in 1994. Run by Srishti Trust, DARE school was already engaged in rehabilitating the specially abled children of plantation workers.

The idea was to create an eco-friendly, non-toxic environment for youngsters and at the same time come up with products that are azo-free and biodegradable.

Aranya seeks to preserve the art of making natural dyes, a craft practice which is a unique repository of community knowledge and heritage. The workers create tie-and-dye fabrics in intricate patterns, along with Batik and Shibori fabrics, which give Aranya the much added value in terms of reviving ancient art forms.

Batik, an ancient art form which enjoys UNESCO heritage status, is a fabric made using a wax-resistant dyeing process by block printing the wax onto the fabric. Shibori is a traditional Japanese art of tie-and-dye, where the cloth is dyed by folding, twisting, compressing, stitching, or capping.

Nature’s colours

Aranya has a repository of infinite varieties of colours to choose from nature. Aranya gathers the nature’s bounty from its discard to create bright, lustrous hues onto its natural fabric.

Dyes are prepared from extracts of leaves, petals, roots, bark and seeds, tea waste, and saw dust which are collected from the region. Some of the locally available natural materials include eucalyptus, Nilgiri kozha or eupatorium, tea waste, and pinecones. For instance, brown is made out of Catechu, lac and Manjista are used to get different shades of red, natural indigo gives blue, turmeric for yellow, pomegranate for yellow and green, and eucalyptus for grey.

In addition, Aranya sources indigo from Tata Coffee in Theni in Tamil Nadu and lac from Janjgir-Champa region of Chhattisgarh.

The unit dyes cotton yarn and fabric, any type of silk yarn and fabric, jute, hemp, bamboo, and pashmina wool. Aranya makes use of all natural fabrics, for the simple reason that only natural fabrics take up natural dyes.

It also makes sure that wastewater is treated and recycled to water the garden and solid waste is made into compost, ensuring that the unit is 100 percent environment friendly.

Making Aranya a success, its people

Victoria Vijayakumar, who heads Aranaya, has contributed greatly to the success of Aranya by her professional and hands-on approach. “I am associated with Aranya from the day of inception. This unit is my second home. Each day is an excitement. The artisan, our differently abled youngsters are our great strength,” she says.

The workers are trained by volunteer trainers for six months in particular skill sets, depending on their aptitude and interest. Workers often come up with new designs, which are often encouraged and accepted in the next of printing.

The workers and trainers are provided with housing, mid-day meals, free transport facility between their homes and the units, and crèche facilities. Schooling is provided for their children as well.

"Instead of being a burden to their immediate family, today they earn good wages and stand on their own feet. Their commitment and enthusiasm has made Aranya what it is today. I am very proud of them," says Ratna Krishnakumar, managing trustee of Srishti Trust.

One of the many happy stories is of 36-year-old Bhanumathi who has been working at Aranya since its inception. Her parents are workers at the tea estates. A welfare officer suggested her parents that she should learn vocational training at DARE, which eventually brought her to Aranya. Bhanumati has travelled to Phulia and Hyderabad to attend workshops to further her knowledge in the dye making and printing processes.

Innovation is the secret to their success. The workers are constantly searching for innovative methods and techniques to keep their work alive and original. One of the workers Arumugam designed a new Shibori technique. Yoshiko Wada, an internationally acclaimed textile artist, named this design Aru-Shibori after him.

“I feel so happy to be associated with this group of children. Aranya growth is a dream to come true. The young interns make Aranya more colorful with their beautiful designs.

Our trainees, to whom we owe a great debt of gratitude to their commitment and energy, have been our inspiration. With no textile background, these young adults who are all physically or mentally challenged have blossomed into wonderful human beings, positive in their outlook, willing to experiment and cross frontiers never tried before. The ones who were depressed on joining soon shook off their burden and joined the main stream to be useful and productive people. That I think has been the most satisfying achievement of Aranya,” says Victoria.

Adding to that, Ratna concludes, "To be able to produce beautiful pieces of work without damaging the environment in anyway is a great achievement."