This man from Ahmedabad has a roofing solution for the third world

Elon Musk created a mini frenzy in the cleantech world when he announced roofing tiles with embedded solar panels, but India already had an innovator who figured out this solution and much more

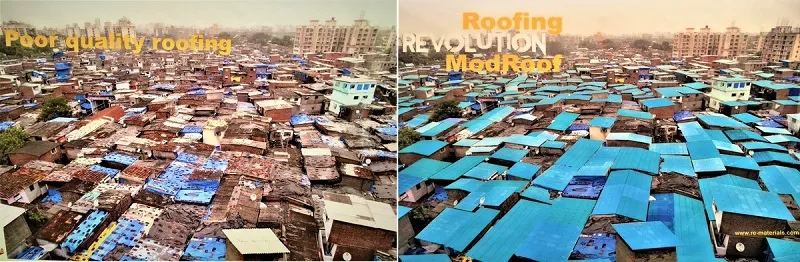

We’ve travelled incessantly across cities and rural India over the past few years gathering stories. One of the recurring questions that arise is about housing and, more specifically, roofing. The way urban slums are coming up and the way rural societies are developing, the industrial world has force-fed a solution that is neither eco-friendly, nor functional, and it does not have an ounce of beauty. Moving ahead from the mud houses with bamboo roofs and other natural materials (we can still very well use them), people are left with two options- expensive RCC or the mighty hot (in summers) and noisy (in monsoons) tin sheets. There are terracotta tiles in some parts but they are prone to breakages.

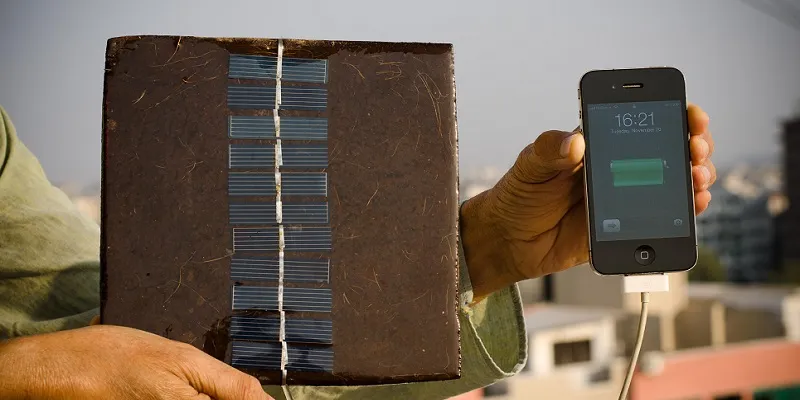

In Ahmedabad, our search for an answer brought us to Hasit Ganatra. A local lad who went to the University of South California to study engineering, Hasit has worked in the fields of rural solar electrification, electric vehicles and low-income housing. While figuring out an affordable housing solution in his last stint, he came across the dearth of proper roofing solutions.

My work in the rural solar electrification project took me to remote parts of the country and during my research around housing as well, I spoke with a lot of locals. And in numerous cases, roofing is the problem! People manage to get the walls together and up but roofing turns out to be the bottleneck

says Hasit from his research.

Concrete is just too expensive and tin sheets are a very poor alternative. “I looked around for materials that can be picked off the shelf but found absolutely nothing. I told the firm supporting me to do housing that solving roofing can create a much larger effect,” says Hasit. He started out by experimenting with materials in his backyard. There had to be a material that is hard, light, waterproof and cost-effective. The answer took time to come.

“People called me crazy, they still do,” Hasit told us at his factory shed in Vattva, the industrial area in Ahmedabad. His company, Re-materials, has rented out six sheds, where 35 people work tirelessly to manufacture a material that can be an answer to good quality, affordable roofing.

Trying out multiple things—paper pulp, agriculture waste, plastic waste, etc. —it took a good 14 months to arrive at a mix that gave the first iteration of the material they have currently. A lot of people in various capacities came in to help Hasit with his experiments. “We rented a small press, got materials in very small quantities and tried out hundreds of combinations to arrive at a composition that worked for us,” recollects Hasit. And from that stage, it took three months more to reach a point where that material was waterproof. For waterproofing, they used a mixture of synthetic resin and a couple of other things, but in the latest development, they’ve managed to get rid of that as well and have a more eco-friendly layer that acts as a water-proofing material.

From the backyard to factory, it has taken a lot of hard work and persistence. Along the way, Hasit managed to get two investors onboard- Deepa and Gayatri Prahlad (family of well known professor Dr. C.K. Prahalad) and Arpit Vyas, an industrialist from Ahmedabad. And Re-material’s ModRoof is now ready for production and scale up.

Over one billion people in slums and villages worldwide are not safe, secure, or proud of their homes because they lack adequate roofing.

And providing a solution for this challenge is ModRoof’s mission.Work has already started. “We’ve made more than 70 installations in Ahmedabad,” says Hasit. The product is ready and the word has started to spread. They already have inquiries from countries like Brazil, Mexico, Morocco and other developing nations. “There is a clear need for such a product and we’re glad to have made something that answers the questions,” says Hasit.

To make the company financially viable, there is still a long road ahead. The company has a pilot manufacturing facility and are looking to expand to implement 500 roofing projects a month to meet their expenses. “That is how the world of manufacturing is. You need to hit some scale to make yourselves a force to be reckoned with. I want this invention to go the masses and not stay on the research desk,” says Hasit.

As a founder, this is a great strength to have for a company that is so heavy on research and development. Most of Re-materials' manufacturing equipment is made in-house. From a pupling machine to a UV tester to an extruder machine, the team at Re-materials has taken up all challenges that have come their way. Give me six months and you’ll see a sprawling cutting-edge research centre. We are a product company but the core is the research in our work

says Hasit. We also saw samples of some other products including roofing tile which has a solar panel embedded (yes, before Elon Musk), modular wall system, furniture made from their material and more.

We went to a few installations and the families seem to be happy with what they have got. Re-materials has partnered with NGOs and a few micro-finance companies to get the installations going. People have come to them after seeing an installation and the word-of-mouth is also spreading in the communities. “We have an all-women sales team. Once a family uses our roof, they become our evangelists and we’ve managed to get a wonderful set of women who’re proud of spreading the work we’re doing,” says Hasit.

But all this comes at its own price. For instance, during a site visit, one of the families had drilled holes in the tiles and installed a Tata Sky inspite of being asked not to. Re-materials already has this problem solved with the new material but to ensure a fool proof solution, they have a team which regularly visits the installations to take feedback. The research mindset was also not easy to get in. “There will always be resistance at the beginning. But once the locals started to get the joy of experimenting and arriving at a solution, they now love the process,” says Hasit.

Re-materials has done a phenomenal job at arriving at a product that fits the market as well as checking most of the eco-friendly boxes. “We are clear in our mission of providing affordable roofing. Being eco-friendly just happened naturally and we’re glad,” he adds. Now, the company is devoting all energy to scaling up operations and moving to a single larger integrated facility from where they can start delivering on the welcome pile of orders.

Checkout Re-material's website and feel free to write in to us at [email protected] if you want an introduction to Hasit or have something to share related to this story.